How We Do It

We acknowledge aqua feed as most valuable feed and understand how critical it is to maintain the quality to maintain fish health and sustainability. Thus we have designed a tailored process in pursuit of high quality & maximum food safety without any compromise.

We acknowledge aqua feed as most valuable feed and understand how critical it is to maintain the quality to maintain fish health and sustainability. Thus we have designed a tailored process in pursuit of high quality & maximum food safety without any compromise.

PROCESSING HIGHLIGHTS

Raw Material Screening

BUYING

Professional dealers buy healthy dicots, without shriveled, contaminated, black or immature seeds

SORTING

Seeds are further sorted to eliminate any undersized seeds

TESTING

Microbial testing is carried out to ensure the absence of feed pathogens for each raw material batch.

Manufacturing

FACILTY

Raw materials are processed under GMP-B2 approved and organic process certified manufacturing facility.

TESTING

Continual monitoring as well as post-production testing ensures a high quality feed product.

PRODUCT

The roasted korma contains 56% protein content. Fieldstones, galactomannan, cellulose membrane, & silica are mechanically expelled which diminishes impurities like saponins, trypsin inhibitors, and tannins to tolerance level.

As per EU/US standards, following are the factors responsible for food pathogens and microbial risks and we have committed measures to eliminate them.

Manhandling

From raw material to packaging, our korma unit is hands free, integrated manufacturing plant. The raw korma is conveyed from guar gum processing unit to korma unit directly through pneumatic lifting and automatic packaging.

Water

No water, steam or moisture is utilized during the manufacturing process.

Industrial Chemicals

Korma processing is completely mechanical without use of any chemicals/ hexane or any other hazardous industrial chemicals as used in soya derivatives.

Smoke or Incomplete Combustion

Highly efficient Riello burners carry out roasting process, from Italy (smoke free, 99% fuel efficiency) and no wood burner or biomass gasifiers are used.

Atmosphere

Our plant is located away from industrial area and township, amidst green fields ensuring fresh air and pollution-free zone.

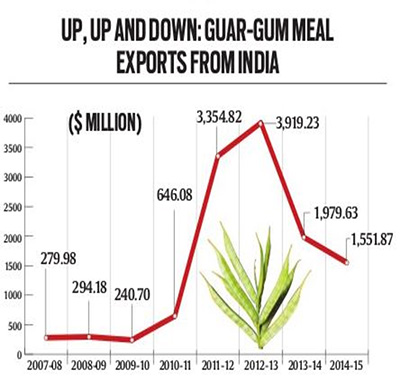

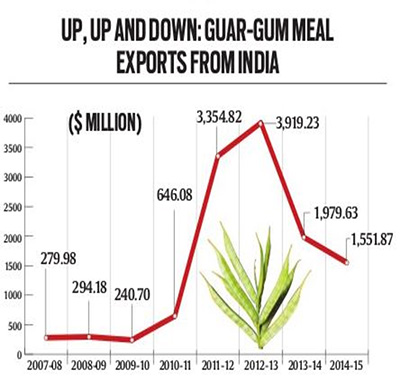

2006-2016: A decade of ‘growth and evolution’

- 2006-2008: Guar was a conventional crop & guar gum was used in industrial applications whereas guar meal was a fodder for ruminants.

- 2008-2010: Even guar couldn’t escape financial crisis as most of the industrial uses were affected.

- 2010-2012: It was the ‘Golden Era’ for guar when it actually got recognized as essential gelling agent by US fracturing industry. At the same time, refining and roasting techniques took place where feed world recognized its importance at new level.

- 2012-2014: Guar got its best prices in between and its end use was widely diversified. Roasted Guar Korma was officially introduced to world in between this period as major vegetable protein source.

- 2014-2016: Aqua industry included this product in their formulation and this was the time when Guar Meal prices were also reached to its peak. Scandinavian countries were became major buyer for Roasted Guar Korma.

- 2016-Continue: Steady growth of Guar industry is taking place at an average of 9% annually . New researches are taking place and competing with SPC. We as a leading company are also working towards the development of GPC and other value added products.

We acknowledge aqua feed as most valuable feed and understand how critical it is to maintain the quality to maintain fish health and sustainability. Thus we have designed a tailored process in pursuit of high quality & maximum food safety without any compromise.

We acknowledge aqua feed as most valuable feed and understand how critical it is to maintain the quality to maintain fish health and sustainability. Thus we have designed a tailored process in pursuit of high quality & maximum food safety without any compromise.

PROCESSING HIGHLIGHTS

Raw Material Screening

BUYING

Professional dealers buy healthy dicots, without shriveled, contaminated, black or immature seeds

SORTING

Seeds are further sorted to eliminate any undersized seeds

TESTING

Microbial testing is carried out to ensure the absence of feed pathogens for each raw material batch.

Professional dealers buy healthy dicots, without shriveled, contaminated, black or immature seeds

SORTING

Seeds are further sorted to eliminate any undersized seeds

TESTING

Microbial testing is carried out to ensure the absence of feed pathogens for each raw material batch.

Manufacturing

FACILTY

Raw materials are processed under GMP-B2 approved and organic process certified manufacturing facility.

TESTING

Continual monitoring as well as post-production testing ensures a high quality feed product.

PRODUCT

The roasted korma contains 56% protein content. Fieldstones, galactomannan, cellulose membrane, & silica are mechanically expelled which diminishes impurities like saponins, trypsin inhibitors, and tannins to tolerance level.

Raw materials are processed under GMP-B2 approved and organic process certified manufacturing facility.

TESTING

Continual monitoring as well as post-production testing ensures a high quality feed product.

PRODUCT

The roasted korma contains 56% protein content. Fieldstones, galactomannan, cellulose membrane, & silica are mechanically expelled which diminishes impurities like saponins, trypsin inhibitors, and tannins to tolerance level.

As per EU/US standards, following are the factors responsible for food pathogens and microbial risks and we have committed measures to eliminate them.

| Manhandling | From raw material to packaging, our korma unit is hands free, integrated manufacturing plant. The raw korma is conveyed from guar gum processing unit to korma unit directly through pneumatic lifting and automatic packaging. |

| Water | No water, steam or moisture is utilized during the manufacturing process. |

| Industrial Chemicals | Korma processing is completely mechanical without use of any chemicals/ hexane or any other hazardous industrial chemicals as used in soya derivatives. |

| Smoke or Incomplete Combustion | Highly efficient Riello burners carry out roasting process, from Italy (smoke free, 99% fuel efficiency) and no wood burner or biomass gasifiers are used. |

| Atmosphere | Our plant is located away from industrial area and township, amidst green fields ensuring fresh air and pollution-free zone. |

2006-2016: A decade of ‘growth and evolution’

- 2006-2008: Guar was a conventional crop & guar gum was used in industrial applications whereas guar meal was a fodder for ruminants.

- 2008-2010: Even guar couldn’t escape financial crisis as most of the industrial uses were affected.

- 2010-2012: It was the ‘Golden Era’ for guar when it actually got recognized as essential gelling agent by US fracturing industry. At the same time, refining and roasting techniques took place where feed world recognized its importance at new level.

- 2012-2014: Guar got its best prices in between and its end use was widely diversified. Roasted Guar Korma was officially introduced to world in between this period as major vegetable protein source.

- 2014-2016: Aqua industry included this product in their formulation and this was the time when Guar Meal prices were also reached to its peak. Scandinavian countries were became major buyer for Roasted Guar Korma.

- 2016-Continue: Steady growth of Guar industry is taking place at an average of 9% annually . New researches are taking place and competing with SPC. We as a leading company are also working towards the development of GPC and other value added products.